Exhausts for heavy commercial vehicles

Experienced manufacturer of high-quality exhaust systems expands to Heavy Duty

FennoSteel is a leading Scandinavian manufacturer of exhaust systems for automotive, agriculture and equipment applications. Our customers include both large european aftermarket distributors and original equipment manufacturers.

Since 2106 FennoSteel has manufactured heavy duty exhausts. We at Fenno have experienced that the Scandinavian clientele deserves a nearby manufacturer that is able to react quickly to orders as well as to the development needs of new products.

SCR silencers

Heavy duty vehicles are large polluters when considering the total emissions from road transport. This is due to number of vehicles but as well their high yearly mileage and high average engine load. From the introduction of Euro 4 emission norm (2005) started the use of aqueous urea solution and Selective Catalyst Reaction (SCR) technology. This means that harmful Oxides of Nitrogen are catalytically reduced to atmospheric Nitrogen. Later, after introduction of Euro 6 norm, heavy commercial vehicle silencers have been equipped with a combination of Diesel Particle Filter (DPF) and SCR. In these designs the DPF removes harmful soot particles and SCR catalyst eliminates NOx.

FennoSteel has currently typical Euro 4, Euro 5 and Euro 6 silencers in the product range. As well silencers for older vehicle are available.

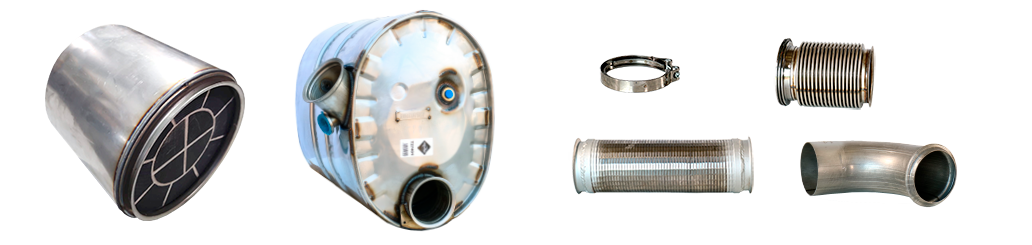

Diesel particle filters and catalytic converters

FennoSteel manufactures diesel particle filters and catalytic converters for most appliations. Our products offer a good quality alternative for original parts. In addition to new DPFs, Fenno as well has a remanufacture program, where DPFs are cleaned and maintenanced against a deposit part. High quality and regulargy maintenanced DPF ensures good fuel efficiency and protects our environment from harmful particles.

Exhaust pipes and mounting components

Different exhaust pipes and mounting components account for more than 90 % of heavy duty exhaust parts. This is understandable when considering the huge variety of different heavy duty chassis applications from tractor to cement mixer. The majority of Euro 3 level heavy duty exhaust parts are of Aluminized steel, where as newer Euro 4, Euro 5 and Euro 6 constructions are of stainless steel. This is because of corroding urea (AdBlue) solution and higher exhaust temperatures required to maintain the SCR catalyst and DPF functionality.

Products

Particle filters and

catalysts

Parts available for most vehicle applications.

Silencers and

pipes

High quality product line for Scania, Volvo and Mercedes.

Mounting

components

High quality mounting component for easy installation.

Quality, people and environment

FennoSteel is well known in the market for the uncompromised quality approach. As a result of this Fenno's product development, production and logistics are ISO 9001 certified by DNV.

Quality is made by the people. We do our best to provide a safe, motivational and encouraging place to work. ISO 45001 certificate is a result of our systematic work in this field.

We at Fenno have put a strong focus on environmental matters. FennoSteel complies with all regulations of the environmental certificate ISO 14001. All materials used in our processes are either re-used or recycled appropriately.

Engine technology and more stringent emission norms challenge exhaust manufacturers

Heavy duty engine technology has developed enermously during the last 20 years. Also engine out emissions and other environmental matters have become very important. Hence, all new commercial vehicles have diesel particulate filters and SCR catalysts for the removal of nitric oxides.

To meet the market requirements with competitive products, FennoSteel collaborates with the leading emission control device manufacturers. By this we ensure working concepts and competence. To make everything alone is not possible.