Busy spring 2021

Spring 2021 has been very busy at FennoSteel. After winter full of Covid talk the sun shine brought back the need for exhausts and gave some fresh ideas for all of us. As usual, there are always challenges and in this year they have been the raw materials prices in the world market. Steel and…

Read MoreNew universal parts catalogue published

We have collected our universal parts to a new catalogue. Now the products start from automotive sizes and go all the way to heavy duty applications. Please download your catalogue from our material bank. In case you have ideas to add new parts to our selection, please do not hesitate to inform your Fenno contact…

Read MoreFenno introduces new SCR catalyst product range for Scania

FennoSteel has introduced a new product line to offer high quality aftermarket catalysts for Scania Euro4 and Euro5 heavy duty vehicles. Included products are oxidation catalysts and selective NOx catalysts for AdBlue systems. Design parameters include OE equivalent catalyst substrates and back pressure together with accurate dimensional tolerances for easy installation. Replaceable Scania parts include…

Read MoreFennoSteel participates Automässan 2020 in Göteborg

FennoSteel welcomes all old and new customers to visit our stand in Automässan 2020 exhibition in Göteborg. We will introduce our new product range with new items in all product categories. Please welcome to our stand in D01:22.

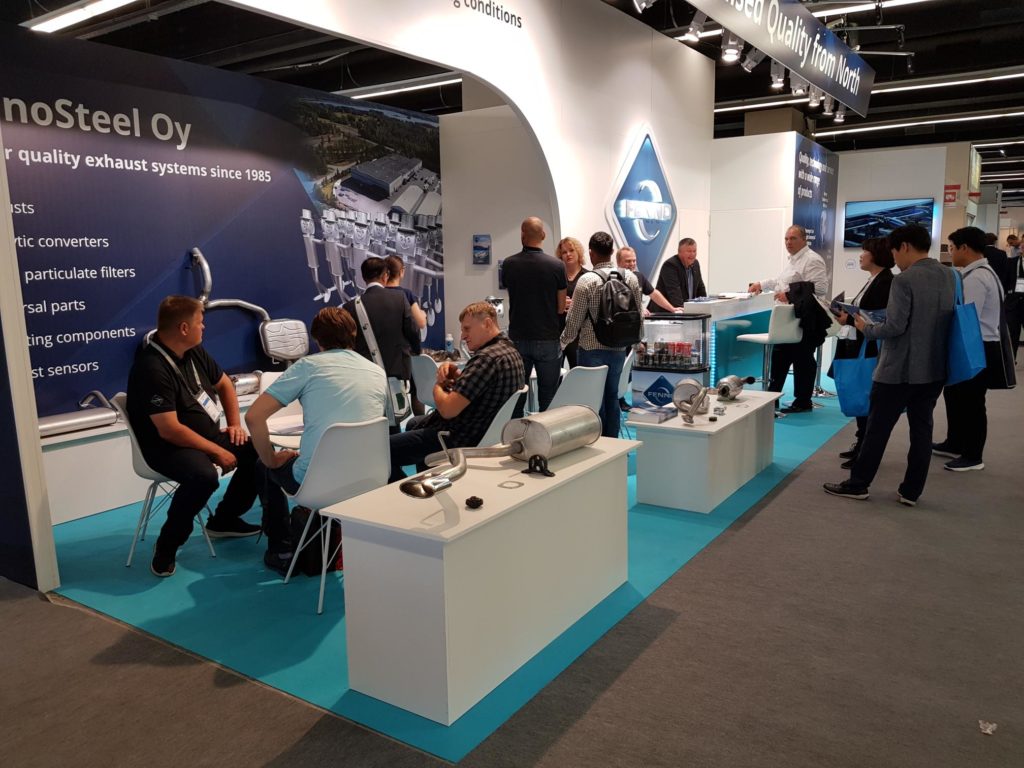

Read MoreThank you for visiting FennoSteel stand in Automechanika

Automechanika 2018 trade show in Frankfurt offered an excellent venue for FennoSteel to meet existing and new business partners and friends. We want to thank all of you and hope to see you soon!

Read MoreFenno participates Frankfurt Automechanika

FennoSteel welcomes all old and new clients to visit our stand in Frankfurt Automechanika. We will introduce our new product catalogue 2018-2019 and as well some interesting heavy duty exhaust components. Please welcome to our stand in hall C6.3 at C05.

Read MoreFennoSteel participated Moscow MIMS autoshow

Automechanika 2018 trade show in Moscow in August collected again the top suppliers for automotive industry under the same roof. FennoSteel stand at Pavillion Forum served customers in Scandinavian style lounge. New products were introduced and especially our new 2018-2019 catalogue and heavy duty truck exhausts. Thanks to our comprehensive product sortiment our customers get…

Read MoreTubelaser

FennoSteel develops the further processing of steel tubes with the fiber-optic tubelaser. There is no other Adige LT8.10 in the Nordig countries, so we are very happy to have this high performance and very automatic machine in our factory. The tube laser is a big step forward and now we are able to handle all…

Read MoreTraffic sign tubes

FennoSteel Oy is a manufacturer of CE marked traffic sign tubes. The manufactured diameters are 60 and 89mm. The lenght can be chosen from 1000 up to 8000mm. Our standard lenghts 2700, 3150, 3500, 4000 and 6000mm you can find straight from the stock. Ask more details and material options from our sales.

Read MoreFENNOSTEEL RECEIVED AN OHSAS 18001 CERTIFICATE

OHSAS 18001 is a framework standard for an occupational health and safety (OH&S) management system. It supports us to put in place the policies, procedures and controls needed to achieve the best possible working conditions and workplace health and safety. An OHSAS 18001 certification demonstrates that a company aligns to internationally recognized best practices with…

Read More